Tag Archives: Shale shaker screen

Shale shaker screen separation process

During the drilling process, the solid-liquid separation process begins when the drilling fluid flows on the shale shaker screen surface after passing through the circulatory system to carry the cuttings back to the wellhead, then through the elevated tank, the buffer tank and the shunting plate till onto the shale shaker screen.This kind of design can reduce the direct impact on the shaker screen.This is also one reason that can influence the longevity of the shaker screen.

Drilling Linear Shale Shaker Manufacturer

Solid-liquid separation is a process, it is impossible to immediately separate all the drilling fluid when the mud fluid just flow to the shaker screen. When a small part of the mud fluid passes through the shaker screen, most of the mud liquid immediately spread out along the shaker screen, forming a layer of mud. Mud layer becomes thinner and thinner with the separation process going on, until at last reaches one certain position,generally called liquid phase termination line. In this process, large solid particles are repeatedly thrown, small particles and liquid passing through the screen into the mud tank to start the next cleaning stage,such as desander and desilter.Over the termination line solid particles continue to move forward until being discharged. The liquid phase termination line is normally located in the 2/3 to 3/4 effective length of the shaker screen when the shale shaker works normally.

Xi’an TR is a professional manufacturer of mud shale shaker and drilling fluid solid control equipment,widely applied in oilfield drilling,mineral mining,HDD and trenchless system,etc.At the same time,TR provide series of shaker screens for our clients,such as frame shaker screen(Swaco Mongoose,Brandt BL-50,Brandt VSM300),

FLC500 flat Shale Shaker Screen

hook strip screen(Derrick FLC series shaker screen) ,hook strip soft screen.

DEERICK FLC2000 Screen|Shaker Screen

TR Solid Control is also an exporter of mud shale shaker,drilling fluid shale shsker and related shaker screen.Welcome to TR Solid Control to consult and guide the mud shale shaker and other solid control equipment.

Contact: Mark

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Call:+86-13186019379

What’s App:13186019379

E-mail: mark@trsolidscontrol.com

Web: www.chinasolidscontrol.com

FLC500 Flat Shaker Screen

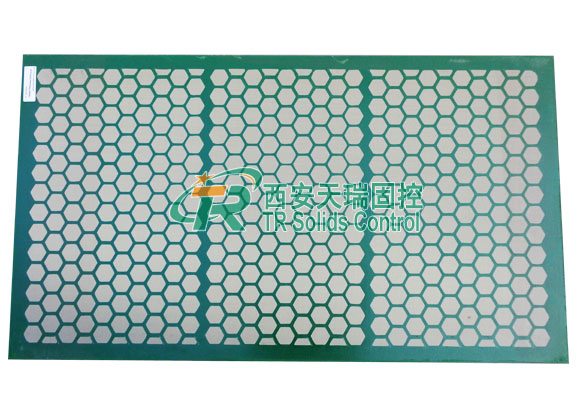

FLC500 flat Shaker Screen constructed with two or three 304 or 316 stainless steel wire cloth layers with a steel backing plate combined together. Because of different mesh size, and steel backing plate, on the condition of using intensity, to get the best and most effective filtering area.

The above of thin wire cloth with middle and the bottom of the thick wire cloth, combined with different thickness steel backing plate together, infinitely enhance the whole screen use intensity.

Because of different model and clients requirement, can choose different steel backing plate form, for example hexagonal, rectangular, square and so on, supporting the above different screen cloth, the above cloth is divided into independent small surfaces, prevent the part excessive expansion damaged, better extend the use lifetime.

FLC 500 Flat Shaker Screen,Flat Shaker Screen,Shale Shaker Screen,Flat Shaker Screen

Advantages of FLC500 Flat Shaker Screen :

1. Wear-resisting

2. long service life,

3. Higher flow rate

4. Easy disassembly

5. Trapping (dreg) effect is good

6. Technical expertise

FLC500 Flat Shaker Screen Parameters

| Product name | Drilling waste management FLC500 flat Shale Shaker Screen for oil filtration |

| Wire mesh material | SS304 SS316 or customized as customers demands |

| Size | 1050*695mm |

| Weight | 6 kgs |

| Screen layers | 2 or 3 layers |

| Mesh count | 20-325mesh |

| Quality standard | compliant with API RP13C Standard |

Remarks:Packaging Details:2 pieces one carton, 20 pcs one wooden case. Out size of the wooden case: 1250*780*1000mm

Shale shaker screen used in solids control equipment are generally made of woven wire cloth, in many different sizes and shapes, with a perforated plate as frame. Our FLC500 Flat Shaker Screen cloth is designed to last longer, handle higher flow rates, resist blinding and remove fine solids. Improved screen life,Increased flow capacity,Lower overall rig screen cost,Available for all shakers.

We are an exporter of shaker screen.TR is a Steel frame screen maufuacturer and china Steel frame screen supplierOur factory approval the API,Drilling Shale Shakers and drilling shaker screen have the API certification.TR solids control is the designed,selling,production,service and delivery of Chinese drilling fluid shakers manufacturers.We will provide the high quality shaker screen and swaco mongoose shaker screen.

Thanks for visiting our website. Please feel free to leave a message if you any questions.

Contact Us:TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Manufacture: No.2 Goods yard road Xianyang City, Shaanxi Province.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:13186019379

Call:13186019379

E-mail:sales@trsolidscontrol.com

E-mail:sales@trsolidscontrol.com

www.solidscontrolequipment.com

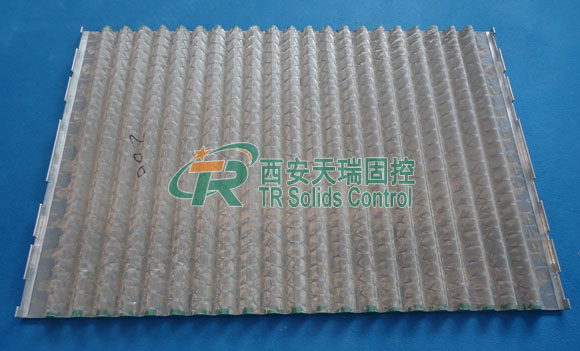

Pyramid shale shaker screen characteristic and main parameter

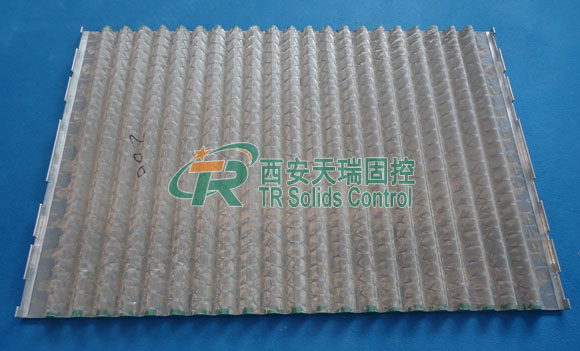

Pyramid shale shaker screen is named by its special pyramid outer appearance.The main features of pyramid shaker screen made by TR Solid Control are as follows:

- It is constructed by 2 or 3 layers of 304 or 316 stainless steel cloth combined together on one steel backing plate.The steel cloth is bent to like pyramid shape or wavelike and then is stuck to the steel backing plate with special glue.

Pyramid shale shaker screen

- Because of wavelike structure,the treatment capacity increased by 25% to 50% compared with the same specification plate screen.

Pyramid shale shaker screen

- The installation method of pyramid screen is just like the hook strip screen or the wedge fixing device.

- The materials can be:stainless steel,plastic,steel and galvanized plate.

TRP Series Of Pyramid Screen Parameter

| Model | Model for Shaker replaced | Mesh Range | Dimension LxW(mm) | Weight(kg) |

| TRP-1 | DERRICK FLC-2000 PMD | 40-325 | 1053X697 | 6 |

| TRP-2 | DERRICK FLC500 SERIES PMD | 40-325 | 1050X697 | 7.8 |

| TRP-3 | BRANDT BL-50 | 40-325 | 635X1253 | 9.3 |

| TRP-4 | TRZS833 | 40-325 | 1080X830 | 10.4 |

TR Solid Control can provide all kinds of shale shaker screen used in oil drilling site,HDD drilling mud recycling system and other waste management systems.Shaker screen is one vulnerable parts in drilling process.TR provide large number of shaker screen to our clients with high quality and competitive price. Welcome to inquiry us about shale shaker screen or other solid control equipment.

Contact: Mark

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Call:+86-13186019379

What’s App:13186019379

E-mail: mark@trsolidscontrol.com

TR Series Hook Strip Flat Shaker Screen Characteristics

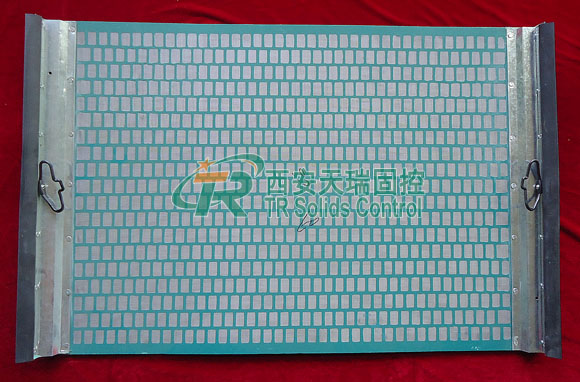

Hook strip flat shake shaker screen is one popular used mud shale shaker screen.Hook strip flat screen is constructed by 2 or 3 layers of metal clothes woven by 304 or 316 stainless steel wire.The 2 or 3 metal clothes are combined together with special glue on the steel backing plate.So the hook strip flat shale shaker screen has a strong structure and an effective drilling cuttings separation effect.

Hook Strip Flat Screen

Because of different model and clients’ requirement,there are several models of the backing plate to be chosen according to the different open holes’ shape on it, such as hexagonal,rectangular,square and so on.Supported by the above mentioned hole-opened backing plate,the whole metal wire cloth is divided into independent small areas and add the supporting strength to prevent the damage from partial excessive expansion when the drilling mud impact on it .So it extends the shaker screen’s serving lifetime.

Hook Strip Flat Hexaganal Shaker Screen

TRH Series Hook Strip Flat Shaker Screen Size Chart

| Model | Model for Shaker | Mesh Range | DimensionLxW(mm) | Weight(kg) |

| TRH-1 | DERRICK FLC-2000 PWP | 40-325 | 1053X697 | 4.8 |

| TRH-2 | DERRICK FLC500 SERIES PWP | 40-325 | 1050X697 | 6.1 |

| TRH-3 | DERRICK FLC313M PWP | 40-325 | 846X697 | 4 |

| TRH-4 | TRZS833 | 40-325 | 1080X830 | 6.7 |

TR Solid Control is one manufacturer of oil drilling solid control system and waste management system including shale shaker screen.TR provides series of solid control equipment including shale shaker,desander,desilter, jet mud mixer,mud agitator,mud gas separator,flare ignition device,shaker screen,etc.TR is also an exporter of above items.

Choosing TR Solid Control is your best choice.TR can provide you one-stop service with high quality products.

Contact: Mark

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Call:+86-13186019379

What’s App:13186019379

E-mail: mark@trsolidscontrol.com

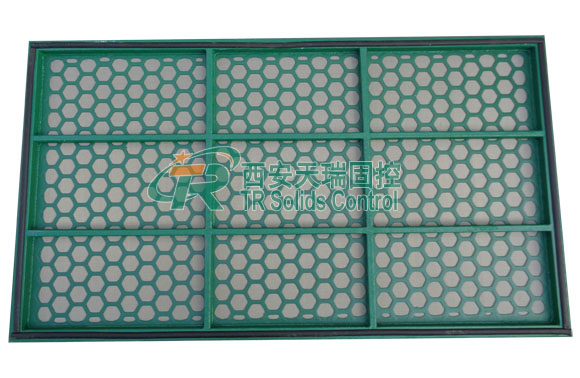

TRF series Steel frame shale shaker screen

TRF series Steel frame shale shaker screen

Frame shaker screen is one commonly used in oil drilling mud shaker screen,sometimes called rock shaker screen.There are two kinds of frame according to the frame material:steel frame and composite frame. TRF series of shale shaker screen refers to the steel frame ones.The shaker screen design is mainly composed of the steel frame and 2 to 3 layers of screen cloth. The stainless steel screen frame is made of high strength square steel or flat steel with reinforced support bars. The screen cloth can be joined to the frame by metal liner or directly bonded to the frame. According to the needs of different customers,TR can supply a variety of specifications of the size of the steel frame screen.

Steel frame screen maufuacturer|china Steel frame screen supplier

Features: wearable, corrosion resistance, high temperature resistance

Specifications: Thickness: 0.3-8mm, short pitch: 3-80mm, long pitch: 3-200mm, the largest width: 2.0mm;Shaker screen mesh size:40-325.

Material: can be divided into ordinary carbon steel, stainless steel, iron, copper, aluminum, titanium, nickel, and so on.

Steel frame shaker screen supplier

TRF Series Steel Frame Shaker Screen Size Chart

| Model | Model for Shaker | Mesh Range | DimensionLxW(mm) | Weight(kg) |

| TRF-1 | BRAANDT BL-50 | 40-325 | 1253X635 | 13.5 |

| TRF-2 | BRANDT VSM300 | 40-325 | 913X650 | 12.6 |

| TRF-3 | SWACO MONGOOSE | 40-325 | 1165X585 | 14 |

| TRF-4 | KENTRON 48 SERIES | 40-325 | 1120X720 | 17.5 |

| TRF-5 | SF300 | 40-325 | 712X1180 | 15 |

| TRF-6 | TRZS703 | 40-325 | 1250X700 | 13 |

| TRF-7 | TRZS852 | 40-325 | 1250X850 | 16 |

| TRF-8 | TRZS752 | 40-325 | 900X750 | 10 |

TR Solid Control is one professional shaker screen manufacturer and exporter specialized in oil drilling solid control equipment and system.TR shaker screen are divided into frame screen,hook strip screen,hook strip soft screen.TR solid control can also provide customized screen and the replacement of Derrick,Swaco and Brandt.TR is your best choice in solid control equipment and shaker screen.

Contact: Mark

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Call:+86-13186019379

What’s App:13186019379

E-mail: mark@trsolidscontrol.com

TR Shale Shaker Screen Using Attentions

Xi’an Tianrui solid control mainly provide drilling solid control equipment and drilling solid control system integration. TR shale shaker is the first level solid control equipment, the shale shaker screen is the very important part of the shale shaker. In addition to the best quality of the screen, there are some attentions must be paid to in the using process in order to improve the screening effect and the screen service life.

Brandt Shaker Screen|Brandt Screen|King Cobra Screen

- Check the shale shaker screen specifications to match the requirements of mud separation before use.

Check whether the mud screen is rupture, hook is loose carefully before use.

Fix the screen on the screen box according to the handbook.Check and confirm without loose.It is forbidden to use metal objects or other hard objects to contact the screen surface to avoid damage to the shaker screen.Rubber or plastic products can contact.Please replace new screen to ensure the screening effect

After inspection without damage, please rinse the shaker screen with water in time for the next re-use.

shale shaker screen,derrick screen,china screen manufacturer,replacement screen of Swaco

TR solid control is one manufacturer specialized in oil drilling solid control equipment and system.TR series of products are widely used in oilfield,tunneling boring system,HDD & trenchless system and so on.TR shaker screen are divided into frame screen,hook strip screen,hook strip soft screen.TR solid control can also provide customized screen and the replacement of Derrick,Swaco and Brandt.TR is your best choice in solid control equipment and shaker screen.

Contact: Mark

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Call:+86-13186019379

What’s App:13186019379

E-mail: mark@trsolidscontrol.com

shaker screen-the important part of your shaker

The screen is one of the most important components of the drilling shale shaker. It is also a metal mesh layer that acts directly on the drilling fluid and is subjected to solid-liquid separation.Applying the international advanced technology, mechanized production methods, Xi’an Tianrui solid control manufactures Tianrui brand shaker screens and replacement screen of internationally renowned brands that ranges from API20 to API400. Xi’an Tianrui screen has the advantages of long life, good separation effect and meets the US API standard together with API certificate. TR solid control oilfield shale shaker is divided into four categories: frame screen(wave and flat screen), hook strip screen(wave and flat screen), hook strip soft screen and slot screen. Xi’an Tianrui not only make their own brand screen, but also can provide customized screen according to client’s requirements.,such as the well-known brands Derrick, Swaco, Brandt.

Hook Strip Flat Screen

The screen is made of metal wire with excellent wear resistance.Generally speaking, any ductile metal or alloy can be used to weave the screen, but commonly used ones are stainless steel, Monel alloy, Brass, tin bronze, aluminum and other alloys. Threaded braided screen has minimal changes in shrinkage or elongation due to temperature,together with the advantages of high strength, long life. Its resistance to temperature changes and corrosion resistance depends on the composition of the metal properties of the screen. Threads of the same (or different) diameter can be knitted into screens of different models (mesh numbers) in various ways. At present, due to the special physical and chemical properties of the drilling fluid, most of the drilling fluid vibrating shaker screens are made of stainless steel wire with strong corrosion resistance.

TR Hook Strip PMD Wave Screen

Xi’an TR Solid Control is one professional mud equipment manufacturer.TR Solid Control provide series of mud treatment equipment such as shale shaker,desander,desilter,jet mud mixer and so on for oilfield,HDD & trenchless system,tunnel boring system,etc. TR is your best choice in drilling mud cleaning.

Contact: Mark

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Call:+86-13186019379

What’s App:13186019379

E-mail:mark@trsolidscontrol.com