Solid Control Spare Parts for Thai Client

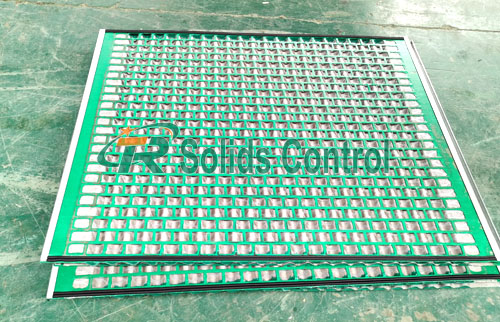

This week, we completed a batch of shale shaker parts and mud cleaner parts. These parts are to replace the shale shaker and mud cleaner ordered by Thai client in 2018 years.

Regarding this order, it mainly includes 3pcs 12” desander cyclones, gauge, manifold inlet, manifold outlet for Swaco 2-12 D-Sander. Also includes hex head screws, hex nuts, lock washes, cable glands for Mongoose shale shaker. They are shipped together for one customer in Africa. In addition to these spare parts, we also provide shaker screens, float mount assy, channel protector, side support assy, cross support assy, lifting device, 10” desander cylone, 4” desilter cyclone for both Derrick and Mongoose shaker and mud cleaner.

TR Solids Control is a professional manufacturer of mud solids control equipment, solid control spare parts, and drilling waste treatment systems integrating product development, production and sales in China for over 11 years. Our solid control equipment and relevant spare parts have been exported to Russia, America, Middle East, South America, Southeast Asia, Central Asia, African, Australia, Europe etc. All of customers are satisfied with the quality and performance. Please contact us freely for any question or interest.

Pyramid Shaker Screens Shipped to Europe

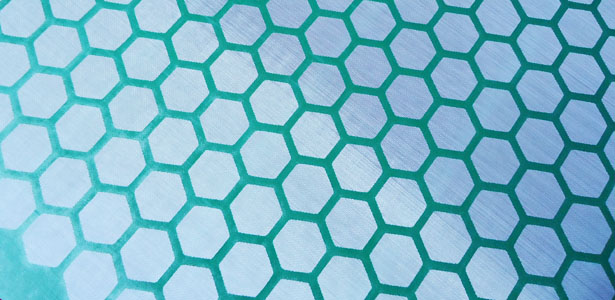

Shaker screens are common vulnerable parts of all kinds shale shaker and mud cleaner in drilling industry. After 10 days’ preparation and production, we completed 10pcs customized pyramid shaker screens for new European customer. They will be used as samples for testing before batch orders for their NOV Brandt shale shaker.

Dimension of these pyramid shaker screens is 915×1200 mm. Our client chose API 60, API 80 and API 100 for larger sieving particles application. Since shipment by train is much faster and cheaper, they preferred this method to the station. Compared with hook strip flat and soft screen, pyramid shaker screen has more available screening non-blank areas. Test shows that the capacity of the shaker gets about a three-fold improvement due to the screen’s corrugations. While this screen still maintains the equivalent cut-point level of flat shaker screen. This application reduces the number of shakers. Thus less space and less cost are realized. Three-dimensional shaker screen is absolute a superior replacement screen for many kinds of shale shakers.

TR Solids Control could supply one-stop service for all your shaker screen requirements. We have been the leading China OEM supplier with quality, high performance shaker screen for over 10 years. Currently our shaker screens are available for FLC Series, Brandt VSM, Cobra Series, Swaco Mongoose and KEM-TRON shale shakers. We accept customized shale shaker screen as per client’s needs. Please send screen models, size, color, or drawings for an inquiry.

OBM Drilling Waste Management Shipment

As the professional manufacturer in China, TR Solid Control could design and manufacture various model Drilling Waste Management or or Cutting Dryer System according to the customers requirement. On May.10th, one new batch of oil based drilling waste management was shipped to our old customer. Currently this system is widely used in Chinese domestic market for compact structure and high efficiency.

This system is composed of TRCD930C vertical cutting dryer, TRLW355N-1 high speed centrifuge, mud tank, centrifuge supply pump and other auxiliary accessories. Processing capacity of our dryer could reach up to 30-50 T/h with basket diameter 930mm. Rotary speed is 900r/min. Bowl diameter of our TRLW355N-1 centrifuge is 350mm, and bowl length is 1250mm. Processing capacity is 40m3/h. TR drilling waste management system can effectively control the moisture content (6%-15%) and oil content (2%-8%) in drilling cuttings, and stabilizes the liquid phase performance.

TR Solids Control is one of the most famous international brand for Mud Solids Control System & Drilling cuttings Management in China. We have one stop service for Solids Control Solution of your oil gas drilling, CBM drilling, HDD, and water well drilling as well as the construction drilling mud treatment etc. For more information about our drilling waste management, please visit: https://trsolidscontrol.en.made-in-china.com/

TRZCQ360 Vacuum Degasser Will be Exported to Pakistan

Xi’an Tianrui Petroleum Machinery Equipment Co., Ltd. is a professional manufacturer of vacuum degasser. TRZCQ360 vacuum degasser ordered by our old customer this time is the fourth order of the customer in our company. Before that, they also ordered two batches of desander for Dubai oilfield site, and the mud gas separator was used in Iraq oilfield site.And this vacuum degasser will be used in Pakistan Rig.

At the time of receiving the inquiry from the customer, the customer attached detailed parameters , which are same as our standard model. Then we quote according to all the requirements of the customer.The customer finally accepted the price and placed a purchase order to us.

The detailed parameters as below:

| Products Name | Vacuum Degasser |

| Model | TRZCQ360 |

| Body Diameter | 1000 mm |

| Capacity | 360 m³/h |

| Vacuum Degree | -0.03~-0.045 MPa |

| Transmission Ratio | 1.72 |

| Degassing Efficiency | ≥95% |

| Main Motor Power | 37 kW |

| Vacuum Pump Power | 7.5 kW |

| Impeller Speed | 880 r/min |

| Explosion Proof Standard | ExdIIBt4 |

| Weight | 1800 kg |

| Dimension | 2400×1500×1850mm |

We are a manufacturer of solid control equipment and solid control system. It can provide customized parameters for customers, that is to produce suitable equipment and systems for customers according to the requirements of customers. If necessary, you can contact and communicate at any time.

Contact number: +86 13186019379.

Email: sunny@trsolidscontrol.com

The Shaker Screens Ordered by Uzbekistan Customer Delivered

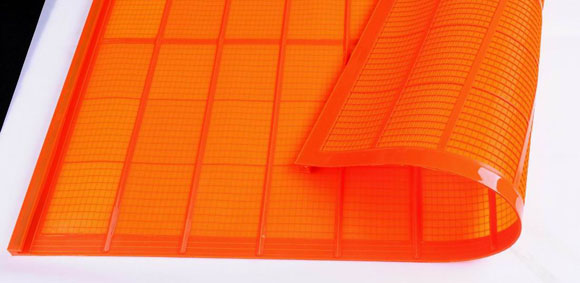

In the middle of April, we received the news that Uzbekistan customer won the shaker screen bid. After confirming the price and quality, the customer immediately placed the order to our factory and we received the advance payment from the customer a week later.

This time, the customer ordered 230 pcs of King Cobra composite screens and 150 pcs of flat screens. The size of composite screen is 1250 × 635mm, the size of flat screen is 1140 × 1210mm.

Intense production began, in order to catch up with the customer’s delivery time, our factory workers worked overtime to produce the screens, and finally delivered the screens to the freight forwarder before the specified delivery time.

TR shale shaker screens are available for Derrick FLC Series, Brandt VSM, King Cobra Series, Swaco Mongoose and KEM-TRON shale shakers. We accept customized shale shaker screen as well. Till now, we have been the leading China OEM supplier of quality with high performance screening surfaces for over 10 years. Our shaker screen has exported to many countries like Egypt, Thailand, US, Pakistan, Dubai, Iraq, Nigeria, Canada and so on. Welcome to consult and order: <sunny@trsolidscontrol.com>.

ZJ30 Oil Gas Drilling System in Production

We received an order of ZJ30 mud circulating system from old customer at the early of April. Now it’s in intense production in our workshop.

Introduction:

Oil Drilling Mud System is a kind of a multi-tank mud system, it is also called solids control system, or mud circulation system for the oil gas drilling rigs. Our TR oil drilling mud system is available for different oil drilling rig sizes from 250HP to 3000 HP with different capacity. With complete five phrase purification equipment shale shaker, vacuum degasser, desander, desilter, decanting centrifuge, TR oilfield solids control system ensures good and efficient treatment effects of removing solids particles and gas bubbles in oil and gas drilling fluids. We design and customize detailed technical drawing of the system according to clients’ special requirements and drilling site application.

TRZJ series mud system can be designed to meet different kinds of conditions in oil and gas drilling field. It has a good performance of cold-resistent, high temperature resistance, anti-explosion, anti-leakage, anti-corrosion, raining proof, adapt to wicked condition of well drilling. It’s very popular among big oil drilling companies.

Features of TR Oil Drilling Mud System:

- Compact structure system for space limited area.

- Harmonious and functional mud tank layout for practical application.

- Trailer mounted mud system for flexible utilizing need.

- Energy saving efficiency is significant since the power consumption of the vibrating motor is low.

- The polyurethane screen has many advantages such as easy operation, low trouble rate, convenient installation and maintenance.

- Winterization frame and heating manifold installed with mud system to keep mud performance in extremely cold area.

Main Specification of TR Oil Drilling Mud System:

| Configure Equipment | ZJ70 | ZJ50 | ZJ40 | ZJ30 | ZJ20 | ZJ10 |

| Mud Tank | ≥270m³/h | ≥200m³/h | ≥180m³/h | ≥160m³/h | ≥160m³/h | ≥80m³/h |

| Storing Tank | ≥160m³/h | ≥120m³/h | ≥80m³/h | ≥80m³/h | × | × |

| Shale Shaker | ≥360m³/h | ≥280m³/h | ≥240m³/h | ≥180m³/h | ≥140m³/h | ≥80m³/h |

| Vacuum Degasser | 360m³/h | 300m³/h | 240m³/h | √ | √ | × |

| Desander | ≥320m³/h | ≥240m³/h | ≥200m³/h | ≥180m³/h | ≥120m³/h | √ |

| Desilter | ≥320m³/h | ≥240m³/h | ≥200m³/h | √ | × | × |

| Middle Speed Centrifuge | 50m³/h | 50m³/h | 40m³/h | √ | √ | × |

| High Speed Centrifuge | 40m³/h | 40m³/h | √ | × | × | × |

| Jet Mud Mixer | ≥300m³/h | ≥240m³/h | ≥200m³/h | ≥180m³/h | ≥120m³/h | ≥80m³/h |

| Shear Pump | ≥120m³/h | ≥120m³/h | ≥120m³/h | ≥120m³/h | ≥100m³/h | × |

| Charging Pump | ≥240m³/h | ≥200m³/h | ≥180m³/h | ≥150m³/h | ≥100m³/h | × |

Horizontal Centrifugal Sand Pumps Produced by TR is Used in Non Oil Drilling

On March 15, 2021, the centrifugal sand pumps produced by TR completed production, packed and sent to the customer’s site for horizontal directional crossing project and replacement of centrifugal sand pump, which is a non oil drilling industry.

TRSB series sand pump is one of the important equipment in oil drilling mud solid control equipment. It is mainly used to supply fluid to desander, desander, slurry mixer and other equipment in drilling fluid circulation system. TRSB series sand pump adopts the combined seal structure design with mechanical seal as the main part and packing seal as the auxiliary part. The wear-resistant parts are made of wear-resistant alloy ductile iron, so as to ensure the stable performance, low failure rate, high efficiency and long service life in the process of field use. All parts can be interchanged with international famous brand pump.

Advantages of TRSB series centrifugal sand pump:

1. The pump shell adopts the coaxial thickening design, which reduces the vibration and wear of the pump shell in operation and prolongs the service life.

2. The pump shell and impeller are made of wear-resistant alloy ductile iron by precision casting, which has higher wear resistance and longer service life than the same industry.

3. The open impeller design effectively reduces the bearing capacity of shaft and bearing, and extends the service life of bearing.

4. The impeller adopts anti loose design to prevent damage to the sand pump when it reverses unexpectedly.

5. The combination of mechanical seal as the main and packing seal as the auxiliary conforms to the seal. The mechanical seal adopts cemented carbide to prevent the leakage of sand pump and reduce the maintenance time of pump.

6. Replaceable shaft sleeve to prevent shaft wear.

7. The bearings are of international famous brands, with stable operation and long service life.

8. Imported fluorine rubber oil seal is selected for oil seal with good cooling performance. Ensure the normal operation of sand pump.

9. All parts can be interchanged with international famous brands to reduce user’s spare parts inventory and purchase cost.

Video Feedback Videos of Vertical Cutting Dryer and Decanter Centrifuge on Site

As China’s domestic environmental protection requirements continue to increase, oil drilling sites also require mud not to be treated on the ground. In addition, this scheme has been widely used in international market of many countries.

Main configured equipment ordered by our client covers TRCD930C vertical cutting dryer, TRLW355N-1 high speed centrifuge, mud tank and other auxiliary accessories. Drilling waste management is known as drilling fluid non-grounding, which refers to the use of mud non-grounding equipment to filter out the waste in drilling fluid. Mud non-ground treatment equipment can turn waste drilling mud into treasure, since oil-based mud is a kind of hazardous waste. Drilling waste management produced by TR Solids Control can make the waste oil-based drilling mud treated and reused, which not only reduces drilling cost, but also meets the requirements of environmental protection.

The followings are live videos of customer feedback.

TR Vertical Cutting Dryer Running Video

TR Decanter Centrifuge Running Video

TR Decanter Centrifuge Running Video

TRZCQ270 Vacuum Degasser for India Market

Vacuum degasser is a special-purpose device and a new type one for gas treatment in drilling fluids. This unit is positioned downstream from mud cleaner, shale shaker and mud gas separator, while hydrocyclones and centrifuges follow in the arrangement. On Mar.31th, the production and loading of TRZCQ270 vacuum degasser was completed in our factory. Along with it, our client also ordered spare parts for two-year operation.

This vacuum degasser will open up the Indian market as a sample for our customer. As the famous trading company, they would like to try other models for end user in oil and gas drilling field. Processing capacity of this unit is 270m3/h(1188GPM). Body diameter is 800mm with vacuum degree -0.03 to -0.045Mpa. Its degassing efficiency can be more than 95%. Transmission ratio is 1.68. It’s matched with one piece vacuum pump with power 3kw. Main motor power is 22kw up to explosion-proof standard. The unit has no moving parts and rely on the density difference between the gas and the mud for removal. The process is simple, yet very effective for well.

We are a professional and well-known manufacturer of solid control system and equipment, drilling waste management in china. Currently our products have been exported to Russia, America, Middle East, South America, Southeast Asia, Central Asia, African, Australia, Europe etc. We will provide our clients high quality products with most reasonable price, meanwhile we also sincerely offer high level after sales service for any home or abroad clients. You are welcomed to consult or visit us any time.

Mud Agitators Exported to Africa

Mud agitator is an ideal device for stirring, mixing liquid and preventing the solid-phase precipitation in the mixture. TR Solids Control could supply both horizontal and vertical type agitators. For horizontal mud agitator, we have two kinds for clients: direct-connecting and coupling one. They have own advantages in the process of operation. On Mar. 23th, 20pcs direct-connecting mud agitators are ready within 4 weeks in our factory. They are going to be exported to Africa.

Our client would use them on their oilfield drilling site for mud mixing application. Motor power for this batch mud agitator is 15kw with explosion-proof standard. Impeller diameter is 950mm with speed 60/72rpm. The structure of this kind agitator is compact and optimized, making it save space in drilling field. We adopt good heat exchange performance, this lets agitator faster cool down. In addition, we use turbo and worm gear speed reducer with the large torque transmission. The revolution is steady, it works reliably and has great merit.

Mud agitators are hot solid control equipment in our company. They are widely used in oil and gas drilling, horizontal directional drilling, tunnel and micro-tunneling, coal bed gas mud mixing etc. Till now, TRJBQ series mud agitators have been exported to Russia, America, Middle East, South America, Southeast Asia, Central Asia, African, Australia, Europe and so on. Are you looking for high efficient mud agitators to support your drilling process? TR Solids Control will be your good choice.