Online Gambling Sparks FASCINATION WITH AC Casinos

Everybody knows there are lots of land-centered casinos around but nonetheless we believe that likely to such places is only going to cost more money for travel costs. See what models us in addition to the others by looking into our Free of charge Spins slots beneath. They are typically match bonus deals which will give you from 50% to 500% of one’s cash back to enjoy that a lot more casino. The cellular casinos are secure, and perhaps even safer compared to the online types as mobile phones aren’t a susceptible to viruses. Free slot modern casino games available and then players from specific countries. Games could be downloaded direct on your own mobile phone. Once you play within an online gambling establishment and make an effort to win money, you’ll create a castle in the atmosphere. Эффективно зарекомендовало себя лично вулкан зеркало , которое аналогично может предложить гостям забаву в демонстрационном режиме.

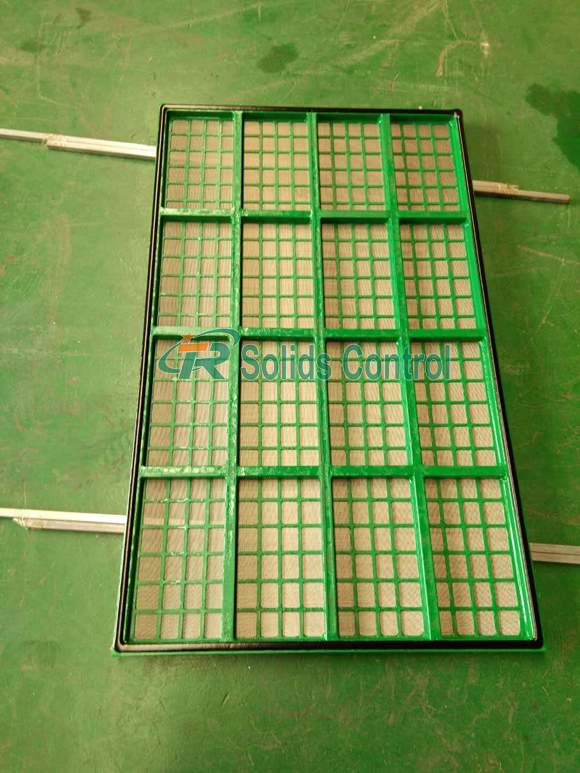

Frame Shaker Screen Shipped to Thailand

TR Solids Control is professional manufacturer of shaker screens in China. We not only supply our own shaker screens, but also can supply replacement shaker screens for international brand like Derrick, Brandt, Mi-Swaco, etc. On Aug.8th, we complete the production of 200pcs frame shaker screen for a Thailand HDD drilling company. This company already owns mud recycling system with TR Solids Control brand. And they are happy with the performance and after sales support. This is the main reason why they repeat orders for spare parts from TR Solids Control.

Regarding the shaker screens our client ordered at this time, mesh range varies from API 80 to API 170. The dimension is 707×1170mm. Screen material is made from S.S304, and frame material is made from iron. They have good separation effect and strong wear resistance. After arrival, they will be used for M400 shale shaker in HDD field.

Below are the main features of our frame type shaker screens:

- TR frame screens are composed of two or three 304 or 316 stainless steel wire cloth layers with a iron backing plate and iron frame combined together. Because of different mesh size and hole size, which can get a better filtering effect.

- Screen bottom adopts high strength iron frame, supporting bar with the moderate tension screen cloth. They are combined together to infinitely enhance the screen intensity and endurance, and get a better filtering effect.

- Mesh sizes ranging from API20 to API400. The whole cloth is divided into independent small surfaces. They can prevent part excessive expansion damage. With a special rubber plug together to repair the damage, which can save time to replace the screen, increase efficiency and reduce cost.

TR Solids Control can supply one-stop service of frame shaker screens. Our screens meet with API standard. Many of them can be totally replaceable with international brands. In addition, our main product shale shaker, mud cleaner, decanter centrifuge, shear pump, centrifugal pump, screw pump, jet mud mixer, vacuum degasser, mud agitator are hot sale. We are looking forward to your quote!

Contact us:

Web: http://www.trsolidscontrol.com/product/shaker-screen/

Email: sunny@trsolidscontrol.com

How to choose the right sand pump.

Sand pumps are widely used in petroleum, chemical, electric power, metallurgy, mining, ship selection, light industry, agriculture, civil and defense sectors. Therefore, how to choose the right the sand pump that we use ourselves is the problem we have to face:

Firstly, before the sand pump is selected, we must first understand the use medium of the sand pump and the requirements of the site:

(1) Characteristics of the medium:

a. the name of the medium, specific gravity, viscosity, corrosivity, toxicity, etc.;

b. the particle diameter and content of the body contained in the medium;

c. Temperature of the medium: (°C).

(2) the pump flow required to use the site:

a. If the minimum, normal, and maximum flow rates have been given in the production process, the maximum flow rate should be considered.

b. If only normal flow is given in the production process, consideration should be given to leaving a certain margin.For the large flow rate of ns>100, the pump is not intended to be lifted, the flow balance is 5%, the pump with a small flow rate of ns<50 and the pump, the flow balance is 10%, the pump with 50≤ns≤100, the flow allowance is also Take 5%. For pumps of poor quality and poor operating conditions, the flow balance should be 10%.

c. If the basic data only gives weight flow, it should be converted into volume flow.

General industrial pumps can ignore the amount of leakage in the piping system during the process, but must consider the impact of the process on the flow. Agricultural pumps that use open channels should also consider leakage and evaporation.

(3) Confirmation of pressure:

the pressure of the sink, the pressure of the drain, and the pressure head loss in the pipeline system.

(4) Pipeline system data:

pipe diameter, length, type and number of pipe fittings, geometric elevation of sink to pressure tank, etc. If necessary, the device characteristic curve should also be made. When designing the piping, pay attention to the following items:

a. Reasonably choose the diameter of the pipeline, the diameter of the pipeline is large. Under the same flow rate, the flow velocity is small, the resistance loss is small, but the price is high, and the pipe diameter is small, which will lead to a sharp increase in the resistance loss, so that the lift of the selected pump is increased. With increased power, both cost and operating costs increase. Therefore, it should be considered from a technical and economic perspective.

b. The discharge pipe and its pipe joints should take into account the maximum pressure that can be withstood.

c. The pipe arrangement should be arranged as straight pipe as much as possible. Minimize the accessories in the pipe and minimize the length of the pipe. When turning, the bending radius of the elbow should be 3 to 5 times the diameter of the pipe, and the angle should be as large as 90. °C.

d. The discharge side of the pump must be equipped with a valve (ball valve or shut-off valve, etc.) and a check valve. The valve is used to adjust the operating point of the pump. The check valve prevents the pump from reversing when the liquid is reversed, and prevents the pump from hitting the water hammer. (When the liquid flows backwards, it will generate a huge reverse pressure, which will damage the pump)

Xi’an TR Solids Control is a professional centrifugal sand pump manufacturer. Welcome customers to Xi’an TR Solids Control to visit and negotiate the drilling fluid sand pump business. We will provide you with the best quality drilling fluid equipment and centrifugal sand pump after-sales service. If you are looking for a qualified supplier of centrifugal sand pumps, then Xi’an TR Solids Control will be your best choice.

Contract us:sunny@trsolidscontrol.com

Фильмы online: плюсы просмотра.

Для большого числа граждан кинематография всякий раз будет весьма хорошим и обожаемым времяпрепровождением. . И подобному найдется примитивное комментарий, поскольку отменные кинофильмы способствуют зарядиться полезной энергетикой их персонажей, унаследовать разряд перед труженический неделькой. .

Why choose TR shale shaker screen?

INTRODUCE

Determination of the specifications of the shale shaker screen:

The specifications of the screen are usually expressed in terms of mesh. The mesh number of the screen is the number of wires or the number of holes per inch of length in the direction of the warp (length) or weft (width) of the screen. For example, 40 mesh means that there are forty meshes per square inch in the screen cloth. The larger the mesh size of the shale shaker screen, the lower the screening rate of the screen, and the smaller the processing amount, the more likely it is to be damaged.

Its main features are as follows:

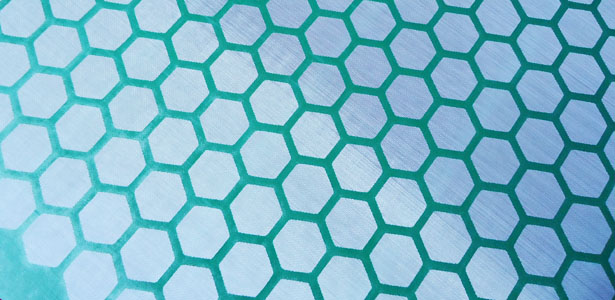

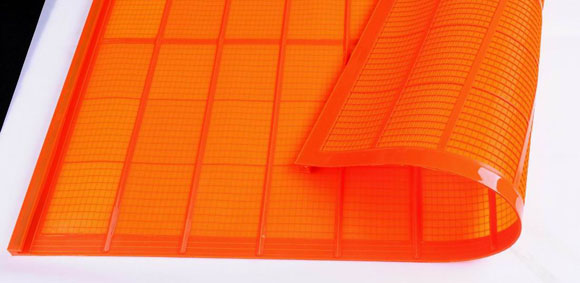

- These products screen constructed with two or three 304 or 316 stainless steel wire cloth layers with a steel backing plate and steel frame combined together. Because of different mesh size and hole size, get a better filtering effect.

- The bottom high strength steel frame, supporting bar with the moderate tension screen cloth, combined together. Infinitely enhance the screen intensity and endurance, get a better filtering effective. Mesh sizes ranging from 20 to 325. The whole cloth is divided into independent small surfaces, prevent the part excessive expansive damaged, with a special rubber plug together to repair damage, can save the time to replace the screen, Increase the efficiency and reduce the cost.

ADVANTAGE

Xi’an Tianrui Solids Control adopts international advanced technology and mechanized production mode to produce Tianrui brand shale shaker screen and alternative screens of international famous brands. The screens available from API20 to API400 are available; Xi’an Tianrui Screen has Long service life and good separation effect, all meet US API standards and have API certificate. Shale shaker screens are mainly divided into four types: frame screens (wave screens and flat screens), hard groove screens (wave screens and flat screens), soft groove screens and slot screens. Xi’an Tianrui not only manufactures our own shale shaker screen, but also can customize the screen according to customer requirements. It can also produce shaker screens such as Drrick, Swaco and Brant, which are well-known foreign brands.

PAREMETER

| API number | Aperture size (mm) | API number | Aperture size (mm) |

| API 20 | >780.0 TO 925.0 | API 120 | >116.5. TO 137.5 |

| API 30 | >550.0 TO 655.0 | API 140 | >137.5. TO 165.0 |

| API 35 | >462.0 TO 550.0 | API 170 | >137.5. TO 165.0 |

| API 40 | >390.0 TO 462.0 | API 200 | >137.5. TO 165.0 |

| API 50 | >275.0 TO 390.0 | API 230 | >137.5. TO 165.0 |

| API 60 | >213.0 TO 275.0 | API 370 | >137.5. TO 165.0 |

| API 70 | >196.0 TO 213.0 | API 325 | >137.5. TO 165.0 |

| API 80 | >165.0 TO 196.0 | API 400 | >137.5. TO 165.0 |

| API 100 | >137.5. TO 165.0 |

PRODUCT PHOTOGRAPH

DERRICK 2000 Screen

DERRICK 500 Screen

CONTACT US

http://tianruisolidscontrol.ecer.com

Email: sunny@trsolidscontrol.com

Whatsapp:+86 13201722103

TRQJ Mud Cleaner for US Trenchless Project

Recently, TR finished the factory delivery inspection of two sets TRQJ200*2S-100*16N mud cleaner that will be used in USA for a big trenchless project. This has the fifth time that this client purchased TR solids control equipment. They give a high evaluation about our product and services.

Drilling fluids mud cleaner, oilfield cleaner, API standard cleaner for sale

Drilling fluids cleaner is the second and third stage solids control equipment for treating drilling fluid. TR Solids Control is professional in manufacturing desilter and desander. It consists of desander, desilter and underflow shale shaker. It has higher cleaning ability compared with separate desander and desilter. In addition to reasonable design process, it equals another shale shaker. It is an high-efficiency equipment in mud solids control system.

Large capacity mud cleaner, China drilling cleaner manufacturer, top quality mud cleaner

Main Specification of TRQJ Series Cleaner

| Model | TRQJ200×1S-100×4N | TRQJ200×2S-100×8N | TRQJ250×2S-100×12N | TRQJ25×3S-100×20N |

| Capacity | 60m³/h | 120m³/h | 240m³/h | 320m³/h |

| Desander Cyclone Specs | 8″ | 10″ | ||

| Desander Cyclone Qty | 1 | 2 | 2 | 3 |

| Desilter Cyclone Specs | 4″ | |||

| Desilter Cyclone Qty | 4 | 8 | 12 | 20 |

| Working Pressure | 0.25~0.4mpa | |||

| Inlet Size | DN125mm | DN150mm | DN150mm | DN200mm |

| Outlet Size | DN150mm | DN200mm | DN200mm | DN250mm |

| Separation Point | 15μm~44μm | |||

| Bottom Shaker | TRZS60 | TRZS752 | TRZS752 | TRZS703 |

| Dimension | 1.51×1.16×2.0m | 1.835×1.23×1.81m | 1.835×1.23×1.81m | 2.42×2.15×2.15m |

| Weight | 600kg | 980kg | 1250kg | 2350 kg |

| Remark | All could be customized without bottom shaker. | |||

TRQJ mud cleaner with short delivery, mud cleaner for trenchless HDD, drilling mud cleaner

TRQJ series drilling cleaner is widely used in oil & gas drilling, trenchless HDD, city bored piling, tunneling construction, Drilling Waste Management, environment protection, mining, etc. Customer’s satisfaction is the highest pursuit of TR Solids Control. We are expecting to be service of you!

http://tianruisolidscontrol.ecer.com

Email: sunny@trsolidscontrol.com

Whatsapp:+86 13201722103

Solids Control Equipment Sent to South America

Recently, TR quality inspectors made the delivery inspection for another batch mud agitators and other solids control equipment. They would be shipped to a South Africa client finally. These equipment ordered including 32pcs 15kw mud agitator, 8pcs 7.5kw mud agitators, 5pcs 55kw centrifugal pumps, 2pcs mud hopper for 2 drilling rigs.

Mud Agitator

Features of TR mud agitator:

- Power available ranging from 3 to 22KW.

- The gearbox adopt worm gear. More reliable.

- Product structure optimization, small size, compact structure.

- Running smoothly, small operating noise, long service life, less wearing parts, and cost-effective.

- Coupling connects motor and gear box directly. Also agitation speed is more stable.

- Good heat exchange performance makes agitator faster cool down.

Mud Agitator

Features of TR centrifugal pump:

- Pump shell using alloy gray iron, longer life.

- Bearings are SKF imported. More assurance on quality.

- Pump parts can be interchangeable with international brands.

- Selection of alloy cast iron impeller, greater resistance to corrosion.

- Bearing lubrication can be oil and grease. Make bearing more adaptable and long life.

- Mechanical seal made of high anti-corrosive alloy. More durable and longer service life.

Mud Agitator

Features of TR mud hopper:

- Tee casted. The main body machines by grinding, sandblasting, rust removal, primer, paint, topcoat. Also its paint film thickness is 125μm.

- Venturi tube and nozzle process through a lathe. Its shape is uniform, and effect is good.

Mixing Rod and Impeller

TR Solids Control has more than eight years’ experience in manufacturing solids control equipment and mud recovery system. Most improtantly, client can get proposal of both single equipment and complex solids control system. Besides that, our main product includes shale shaker, mud cleaner, decanter centrifuge, mud agitator, centrifugal pump, jet mud mixer, etc. Welcome call and ask for a quote!

http://tianruisolidscontrol.ecer.com

Email: sunny@trsolidscontrol.com

Whatsapp:+86 13201722103

Drilling Waste Management Perform Well in Singapore Field

Recently, TR independent R&D drilling waste management has received favorable evaluation from customer at the drilling site in Singapore. Feedback from customer said that TR skid-mounted drilling waste management performs well. It provides an effective solution for them to treat slurry and waste in the pit on their rig site. They are considering starting up the further cooperation with us by placing order on TR module type oil sludge treatment system with large handling capacity.

TR drying shaker

This drilling waste management chosen by our Singapore client is relatively simple. It is divided into two units-waste collection unit and liquid phase separation unit. Waste collection unit consists drying shaker, screw conveyor, mud collection tank, mud agitator etc. Its working principle is transferring the waste residue treated by shale shaker, desander, desilter and decanter centrifuge to the high-frequency drying shaker through screw conveyor. Big particle cuttings in solids control equipment are separated, and liquid enters collection tank for buffering and pretreatment. Liquid separation unit is mainly composed of a program-controlled diaphragm filter press. Solid phase particles are finally separated by a filter press. Separated solid phase can be directly transported. Liquid phase can be carried to the mud circulation system for reuse through mud sand pump.

Drill cutting treatment system

The emergence of drilling waste management has successfully solved the problem of inefficient disposal of drilling waste. TR Solids Control is a lead and professional manufacturer of drilling waste management in China. We have unique slurry treatment solution in oil exploration, sewage treatment, bored piling, and horizontal directional drilling. Contact with us for more details now!

Web: http://www.trsolidscontrol.com/

http://tianruisolidscontrol.ecer.com

Email: sunny@trsolidscontrol.com

TRCS300-2S Mud Desander Delivered to Vietnam

Mud Desander is solids control equipment with a set of desander cyclone to separate sand from drilling mud in drilling rigs. It is installed on top of the mud tank following the shale shaker and vacuum degasser but before desilter. On July.23th, TR finished the factory delivery inspection of one set TRCS300-2S desander that would deliver to a Vietnam client. This is the third time that this client orders our solids control equipment.

TRCS300-2S Mud Desander

Regarding the TRCS300-2S mud desander delivered, its handling capacity reaches up to 280m3/h. It consists of 2pcs 12” high chromium cyclones. Working pressure is 0.2~0.4Mpa. The separation point of our desander can be up to 45~75μm. This type of desander is without bottom shaker, it has compact design with small footprint. It’s can be replaceable with Brandt mud desander. But has much competitive price and good performance. This is why our client chose TR equipment used in their drilling field. They gave high evaluation on our solids control equipment.

TRCS300-2S Mud Desander Delivered

TR Solids Control could supply high quality desander with good price. Our TRCS Series desander is widely used in oil & gas drilling, trenchless HDD, Drilling Waste Management, city bored piling, tunneling construction, etc. Customer’s satisfaction is the highest pursuit of TR Solids Control. We are expecting your inquiry at any time!

Web: http://www.trsolidscontrol.com/

http://tianruisolidscontrol.ecer.com

Email: sunny@trsolidscontrol.com

Xi’an Tianrui centrifugal pump and mud agitator once again went abroad and be sent to the foreign drilling site

The TRSB8×6-13 centrifugal pump and TRJBQ11 mud agitator manufactured by Xi’an Tianrui, once again went out of the country and be sent to the Romanian drilling site.

TRSB8×6-13 centrifugal pump

TRJBQ11 mud agitator

Centrifugal pump and mud agitator are essential solids control devices in the mud loop system of the drilling site. The centrifugal pump can supply mud to the desilter. The choice of centrifugal pump directly affects the treatment effect of the desilter. Centrifugal pumps can also form weighting devices that alter the density, viscosity, water loss, etc. of the drilling fluid. Centrifugal pumps can also be used as mud pumps to assist in grouting. A refill pump using a perfusion pump and a wellhead. The mud agitator is designed to maintain the uniformity of the drilling fluid and suspend the solid phase particles in the drilling fluid to ensure the reliability of the drilling fluid.

Xi’an Tianrui TRSB8×6-13 centrifugal pump is equipped with a 55 kW explosion-proof motor. The pump has an inlet of 8 inches, an outlet of 6 inches, an impeller diameter of 13 inches, a flow rate of up to 275 cubic meters per hour, and a lift of 35 meters.

The centrifugal pump body produced by Xi’an Tianrui is made of alloy cast iron and cast by precision casting technology. It not only has beautiful appearance and long service life; the seal of the pump is sealed with mechanical seal and asbestos packing, and the sealing effect is more remarkable; the bearing imported SKF bearing The oil seal is sealed with imported fluoro rubber, and the bushing is made of stainless steel, which reduces the replacement of wearing parts and reduces the cost of customers. The most important thing is the centrifugal sand pump produced by Xi’an Tianrui. Accessories can be interchanged with accessories from American Mission pumps, and replacement of accessories for customers also adds to the manufacturer’s choice.

Web:http://www.trsolidscontrol.com/

http://www.tr-screen.com/xian-tianrui-cen…and-mud-agitator/

Email:sunny@trsolidscontrol.com