TRJQB6545 Shear Jet Mixing Devices Enter the Shield Construction Site Again

The TRJQB6545 shear mixing devices produced by TR have been put into the shield construction site again.

Shield machine is a kind of special construction machinery for tunnel excavation. Modern shield tunneling machine integrates optical, mechanical, electrical, hydraulic, sensing and information technology. It has the functions of excavating and cutting soil, conveying soil ballast, assembling tunnel lining, surveying and guiding deviation correction. It involves many disciplines and technologies such as geology, civil engineering, machinery, mechanics, hydraulic pressure, electricity, control, measurement and so on The geological design and manufacturing of “tailor-made” style, the reliability requirements are very high. Shield tunneling machine has been widely used in subway, railway, highway, municipal, hydropower and other tunnel projects. The shear mixing device produced by Xi’an Tianrui is mainly used for slurry pressure shield. A large amount of slurry is needed in the construction process, and the composition of the required slurry varies according to different working conditions. Therefore, it is necessary to use the shear mixing device to mix the slurry. Through the slurry shear mixing device, the added materials can be more fully fused with the slurry.

The mixing device of mud shear pump is composed of the main body of the shear pump and the shear funnel, which can provide high shear for the rapid hydration of polymer (and clay). The use of the shear mixing device can reduce the amount of polymer by more than 15% and the amount of bentonite by more than 30%. It also improves the loss of mud cake and fluid flow, reduces the shear ratio rate of drilling fluid, and increases the shear rate of drilling fluid Gel strength;

Xi’an Tianrui is a professional mud separation equipment manufacturer. The shear mixing device is one of the equipment in the shield slurry treatment system produced by the company. The company can provide a complete set of shield slurry separation system for the shield construction. If you need slurry separation, you can contact at any time.

A Batch of Shale Shaker Parts Delivered to Domestic Customer

The spare parts of FLC2000 shale shaker ordered by domestic customer have been produced and used to replace the vulnerable parts of customer’ shale shaker. This is the second time that customer has ordered from our company, including bolts, side supports, lateral supports, damping strips, and rubber springs.

We supply

| Item | Name | Part Number |

| 1 | Super G force vibration motor | SGX55-15-380/400-5-001SGX-44-15-380/400-5-001 |

| 2 | Oil seal (inner seal) | G0006038 |

| 3 | Oil seal (outer seal) | G0006040 |

| 4 | Rubber bushing element | |

| 5 | Runner seal | 642979 |

| 6 | Lateral support | 1649954 |

| 7 | Quick bolt assembly | 6417-06 |

| 8 | Shaft | G0006002 |

| 9 | Inner bearing | G0006005 |

| 10 | Ring | G0006006 |

| 11 | Outer bearing | G0006008 |

| 12 | Packing (graphite) | G0006010 |

| 13 | Packing | G0006011 |

| 14 | Root (Teflon) | G0006012 |

| 15 | Mechanical seal | G0006013 |

| 16 | Axle sleeve | G0006015 |

| 17 | Packing box | G0006017 |

| 18 | Impeller5*6*11 | G0006021 |

| 19 | Impeller6*8*14 | G0006024 |

| 20 | Oil seal kit | G0006037 |

| 21 | Inner seal | G0006039 |

| 22 | Bearing outer seal | G0006040 |

| 23 | Washer Kit | G0006041 |

| 24 | Bearing inner washer | G0006042 |

| 25 | Bearing lock nut Kit | |

| 26 | NEMA Standard explosion proof | 15010-01 |

| 27 | Threaded pipe | NPLE-75X600-C |

| 28 | Sealing plate | CRH-EYS-216 |

| 29 | Pipe joint | CRH-UNY 205 |

| 30 | Threaded pipe | NPLE-75-COND |

| 31 | Threaded pipe | NPLE-75X200-C |

| 32 | Elbow | CRH-EL29 |

| 33 | Elbow | CRH-EL296 |

| 34 | Threaded pipe | NPLE-75X400-C |

| 35 | Pipe plug | SHPP-75 |

| 36 | Threaded pipe | COND-75X650 |

| 37 | Junction box | CRH-EAJT36 |

| 38 | Pipe joint | CRH-ES32 |

| 39 | Pipe plug | SHPP-100 |

| 40 | Threaded pipe | COND-75X250 |

| 41 | Cable assembly | 11881-01-002 |

| 42 | Manual switch | SQD-2510-MC03 |

| 43 | Fuse | PE-S-014 |

| 44 | Hydraulic pump | G0001992 |

| 45 | Bolt assembly UN3/8 | 12048-00 |

| 46 | Damping rubber | 1129-00 |

| 47 | Cyclone cone (4 inch desilter assembly) | 10523-12 |

| 48 | Cyclone cone (10 inch desilter assembly) | 6066-51 |

| 49 | Belt | PP1250 |

| 50 | Pressure gauge | STR-350-1000 |

| 51 | Side support | 6417-01 |

| 52 | Lateral support | 6417-06 |

| 53 | Curved neck | 6431-00 |

| 54 | Supporting frame | 181-Q-30-304 |

| 55 | Wrench with universal joint | 5925-01 |

| 56 | Runner seal | 3660-05-30 |

| 57 | Quick coupling | Vic-2-78 |

| 58 | Hydraulic hose | 7308-08-72 |

| 59 | Fuse | SQD-B7.70 |

| 60 | Degassing compressor | BW519292(ING-V255BARE) |

| 61 | Degassing motor | BAL-M7047T-1/M15B |

| 62 | Cable | 11881-01-002 |

| 63 | Pyramid screen 35mesh | PMD48-30DX-A35 |

| 64 | Pyramid screen 40mesh | PMD48-30DX-A40 |

| 65 | Pyramid screen 45mesh | PMD48-30DX-A45 |

| 66 | Pyramid screen 50mesh | PMD48-30DX-A50 |

| 67 | Pyramid screen 60mesh | PMD48-30DX-A60 |

| 68 | Pyramid screen 70mesh | PMD48-30DX-A70 |

| 69 | Pyramid screen 80mesh | PMD48-30DX-A80 |

| 70 | Pyramid screen 100mesh | PMD48-30DX-A100 |

| 71 | Pyramid screen 120mesh | PMD48-30DX-A120 |

| 72 | Pyramid screen 140mesh | PMD48-30DX-A140 |

| 73 | Pyramid screen 140Fmesh | PMD48-30DX-A140 |

| 74 | Pyramid screen 170mesh | PMD48-30DX-A170 |

| 75 | Pyramid screen 200mesh | PMD48-30DX-A200 |

| 76 | Pyramid screen 35mesh | PMD48-30HP-A35 |

| 77 | Pyramid screen 40mesh | PMD48-30HP-A40 |

| 78 | Pyramid screen 45mesh | PMD48-30HP-A45 |

| 79 | Pyramid screen 50mesh | PMD48-30HP-A50 |

| 80 | Pyramid screen 60mesh | PMD48-30HP-A60 |

| 81 | Pyramid screen 70mesh | PMD48-30HP-A70 |

| 82 | Pyramid screen 80mesh | PMD48-30HP-A80 |

| 83 | Pyramid screen 100mesh | PMD48-30HP-A100 |

| 84 | Pyramid screen 120mesh | PMD48-30HP-A120 |

| 85 | Pyramid screen 140mesh | PMD48-30HP-A140 |

| 86 | Pyramid screen 170mesh | PMD48-30HP-A170 |

| 87 | Pyramid screen 200mesh | PMD48-30HP-A200 |

Axial Piston Pump Delivered to Kenya Customer

Kenya’s old customers ordered a QL80YCY14-1BkF axial piston pump at the beginning of this month, which was delivered on November 23th to the customer’s designated forwarder in Guangzhou.

CY14 axial piston pump is an axial piston pump with oil distribution plate and cylinder body rotating. Compared with other types of pumps, it has the advantages of simple structure, small volume, high efficiency, long life, light weight, strong self-priming ability and so on. It is suitable for machine tools, forging, metallurgy, engineering, mining machinery and other hydraulic transmission systems. The pump only needs to change the motor oil distribution plate, and can also be used as a hydraulic motor.

If you need any axial piston pump, please feel free to contact us for inquiry.

TR centrifugal pump sent to overseas drilling site.

TR centrifugal pump TRSB3×2-9(5.5kw) sent to overseas drilling site.

Centrifugal pump plays an important role in the mud solid control system. In terms of mud supply, it is mainly used to supply mud to desander, desilter, centrifuge and other solid control equipment; in slurry mixing and pulping, it is matched with jet mixing funnel to form a jet mixing device, which can be used as make-up pump and filling pump to match mud pump for drilling site use.

TRSB series oil drilling fluid centrifugal pump is improved on the basis of a large number of centrifugal pumps at home and abroad. The sealing technology adopts the comprehensive seal of packing seal and mechanical seal. The new and unique design can avoid oil leakage to a great extent, with stable operation and long service life.

The centrifugal sand pump produced by Xi’an Tianrui Petroleum Machinery Equipment Co., Ltd. has been widely used in oil & gas drilling, Metro shield construction, building piling construction and other construction sites, and has been well received. Please call us for consultation, order and order hotline:+86 13186019379

Oil Based Mud Not-landing System Ready for Shipment

The oil-based mud not landing system customized by a domestic customer helps the environmental protection of oil drilling mud not landing again. With the continuous improvement of domestic environmental protection requirements in China, in order to respond to and adapt to the national environmental protection requirements, the oil drilling site also requires mud not to land

Mud not landing system is the common name of drilling waste treatment, also known as drilling fluid does not land, refers to the use of mud not landing equipment to screen the waste in drilling fluid. The equipment for mud not falling to the ground generally includes drying shaker, drilling cuttings dryer and high-speed mud centrifuge.

Drilling waste mud can be turned into treasure by the mud treatment equipment without landing, because oil-based mud is a kind of hazardous waste, and the state has strict requirements for hazardous waste treatment. The mud treatment equipment produced by TianRui can reuse the waste oil-based drilling mud after treatment, which not only reduces the drilling cost, but also meets the requirements of environmental protection.

TianRui solid control has always adhered to the enterprise concept of “customer satisfaction is the highest pursuit of TianRui solid control”, and constantly develops new mud purification equipment. We thank our customers for their trust in us, and we will continue to work hard to make greater contributions to drilling mud purification and national environmental protection.

TR Solids Control attends the 2020 China Marine Economic Expo.

TR Solids Control attends the the 2020 China Marine Economic Expo will be held in Shenzhen Convention and Exhibition Center from October 15th to 18th. Our booth number is 1B-T022 . We exhibited TRCD800 vertical cutting dryer,TRSB3×2 centrifugal pump head,TRLWF450X1250N decanter centrifuge and TRZS584 shale shaker. Welcome all partners and customers to visit our booth and discuss cooperation. We are sincerely looking forward to your visiting and consulting.

In this exhibition, we showed our newly designed drill cuttings dryer and Mission series centrifugal pump. Vertical cutting dryer is a type of drying machine for treating sludge in drilling waste management. It can be called vertical centrifuge from structure. Centrifugal Pump is used for transferring slurry or water. It can be used as feeding pump for desander and desilter, or used as mixing pump for jet mud mixer. From 930 series vertical cutting dryer to 800 series dryer, from SB8×6 centrifugal pump to the SB3×2 centrifugal pump, the classic designs of TR conform to the important development of oil drilling environmental protection equipment requirements.

We also showed TRLW series decanter centrifuge is that widely used in trenchless HDD, city bored piling, oil & gas drilling, Drilling Waste Management, tunneling construction, environment protection, chemical Industry, food industry, Pharmaceutical Industry,Oil Sludge Dewatering Systems, Coal Bed Gas Solids Control System, Oil Mud Seperation, mining, Water Drilling etc. And TR series shale shaker is a high strength vibrating screen independently in order to meet the domestic and international market demand and environmental protection requirements. Dual motion shaker with three motors,two kinds of motion trajectory can be switched at will to meet different needs of customers.

TR Solids Control is a well-know manufacturer of solids control equipment in China. We have established a complete quality control system, all products & equipment manufactured as per international standard and API standard. At present, our company has formed more than 50 series and more than 100 specifications of products, which have been widely used in all oil fields in China and have been exported to Europe, America, Southeast Asia, the Middle East, Central Asia, and North Africa and other regions.

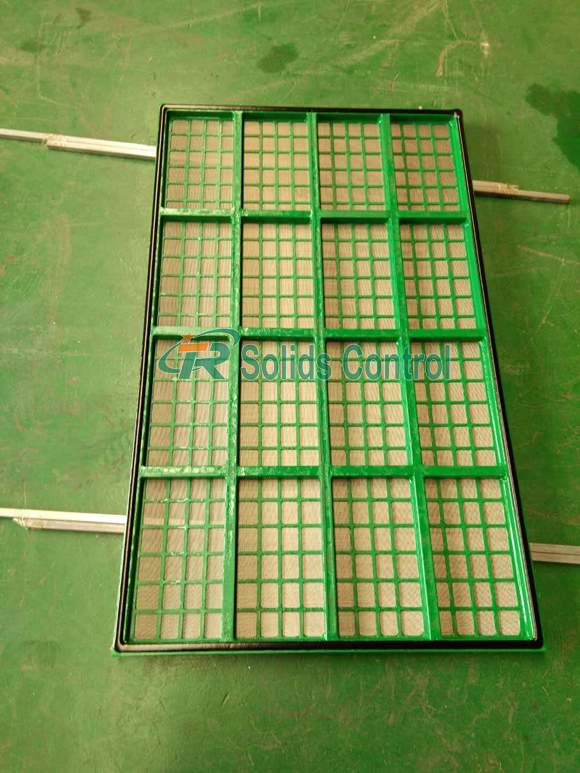

Frame Shaker Screen Shipped to Thailand

TR Solids Control is professional manufacturer of shaker screens in China. We not only supply our own shaker screens, but also can supply replacement shaker screens for international brand like Derrick, Brandt, Mi-Swaco, etc. On Aug.8th, we complete the production of 200pcs frame shaker screen for a Thailand HDD drilling company. This company already owns mud recycling system with TR Solids Control brand. And they are happy with the performance and after sales support. This is the main reason why they repeat orders for spare parts from TR Solids Control.

Regarding the shaker screens our client ordered at this time, mesh range varies from API 80 to API 170. The dimension is 707×1170mm. Screen material is made from S.S304, and frame material is made from iron. They have good separation effect and strong wear resistance. After arrival, they will be used for M400 shale shaker in HDD field.

Below are the main features of our frame type shaker screens:

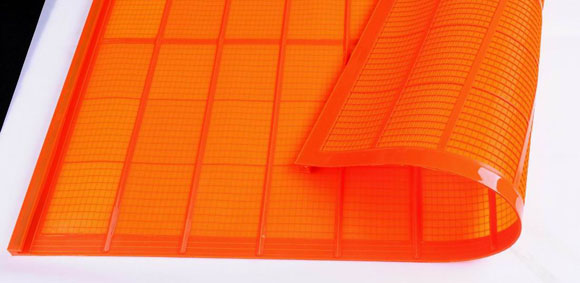

- TR frame screens are composed of two or three 304 or 316 stainless steel wire cloth layers with a iron backing plate and iron frame combined together. Because of different mesh size and hole size, which can get a better filtering effect.

- Screen bottom adopts high strength iron frame, supporting bar with the moderate tension screen cloth. They are combined together to infinitely enhance the screen intensity and endurance, and get a better filtering effect.

- Mesh sizes ranging from API20 to API400. The whole cloth is divided into independent small surfaces. They can prevent part excessive expansion damage. With a special rubber plug together to repair the damage, which can save time to replace the screen, increase efficiency and reduce cost.

TR Solids Control can supply one-stop service of frame shaker screens. Our screens meet with API standard. Many of them can be totally replaceable with international brands. In addition, our main product shale shaker, mud cleaner, decanter centrifuge, shear pump, centrifugal pump, screw pump, jet mud mixer, vacuum degasser, mud agitator are hot sale. We are looking forward to your quote!

TR Solids Control attends the 4th China International Industrial Products Purchasing Exhibition

TR Solids Control attends the 4th China International Industrial Products Purchasing Exhibition held in Baoji city from Sep.3rd to Sep.5th. Our booth number is A570. We exhibited TRCD800 vertical cutting dryer & TRSB3×2 centrifugal pump head. Welcome all partners and customers to visit our booth and discuss cooperation. We are sincerely looking forward to your visiting and consulting.

TR vertical cutting dryer and centrifugal pump in Baoji Purchasing Exhibition.

In this exhibition, we showed our newly designed drill cuttings dryer and Mission series centrifugal pump. Vertical cutting dryer is a type of drying machine for treating sludge in drilling waste management. It can be called vertical centrifuge from structure. Centrifugal Pump is used for transferring slurry or water. It can be used as feeding pump for desander and desilter, or used as mixing pump for jet mud mixer. From 930 series vertical cutting dryer to 800 series dryer, from SB8×6 centrifugal pump to the SB3×2 centrifugal pump, the classic designs of TR conform to the important development of oil drilling environmental protection equipment requirements.

TRCD730 vertical cutting dryer is our newly designed for drilling waste management,

TR Solids Control is a well-know manufacturer of vertical cutting dryer and centrifugal pump for more than 10 years in China. We have established a complete quality control system, all products & equipments manufactured as per international standard and API standard. At present, our company has formed more than 50 series and more than 100 specifications of products, which have been widely used in all oil fields in China and have been exported to Europe, America, Southeast Asia, the Middle East, Central Asia, and North Africa and other regions.

Sources of Waste Drilling Mud and Its Impact on Environment

1、 Sources of drilling waste mud

In the process of oil and gas exploration and development drilling, drilling mud is an important guarantee to improve the drilling efficiency, which plays a role in supporting well side, lifting cuttings and cooling bit. At the same time, it also plays the role of lubricating drilling tools, improving drilling speed, preventing well from protecting production layer, and is an essential material to ensure the smooth drilling work. In order to achieve the purpose of safe and rapid drilling, more and more types and quantities of drilling fluid and chemicals are used, which will inevitably produce a lot of waste.

Drilling solid waste includes drilling mud and cuttings extracted from the drilling process, and the waste mud is the largest content of drilling waste. The requirements of drilling technology for mud are higher and higher, the mud system is increasing day by day, and the formula is more and more complex, generally containing heavy metals, oil, alkali and other compounds. In the process of mud circulation, waste slag and waste slurry need to be continuously removed, and all of them need to be removed after the completion of drilling, and become waste slurry. Due to the characteristics of oil drilling field operation, almost all the waste at the construction site is discharged and stored in the waste mud storage pit. Finally, a multiphase stable colloidal suspension mixture composed of clay, weighting materials, various chemical treatment agents and associated sewage, oil and water, drilling cuttings and so on is formed.

2、 Impact of drilling waste mud on Environment

Due to the complex composition of drilling waste mud, the impact on the environment is also multifaceted.Due to the high fluidity of drilling production, the pollution area is large and the area is wide.

- Salt, alkali and drilling cuttings of salt rock in waste drilling fluid not only cause soil hardening, but also inhibit the absorption of nitrogen and phosphorus by crops. Meanwhile, the migration of soluble salt will pollute groundwater.

- Heavy metal ions such as chromium ion, lead ion and so on are very difficult to be degraded by plants passively, which will affect the growth of plants and the reproduction of microorganisms in the soil, and these heavy metal ions will enter the human body through the food chain. It is harmful to human health and safety.

- After oil enters the water body, it forms floating oil, which affects the exchange of oxygen between air and water.

- Sulfide in water is easy to disperse in the air from the water, which produces odor and has toxicity.

Therefore, it is of great significance to the purification of drilling mud.

Composite Shaker Screens Shipped to Middle East

Shaker screens are common vulnerable part of shale shaker and mud cleaner. Composite type screens are perferred among clients for higher abrasion resistance and longer service time. At last week, we shipped 200pcs Mongoose composite shaker screens to a big drilling company in Middle East. They all passed strict inspection and with high quality carton box and wooden case package as per requirement before delivery.

Mongoose composite shaker screens shipped to a big drilling company.

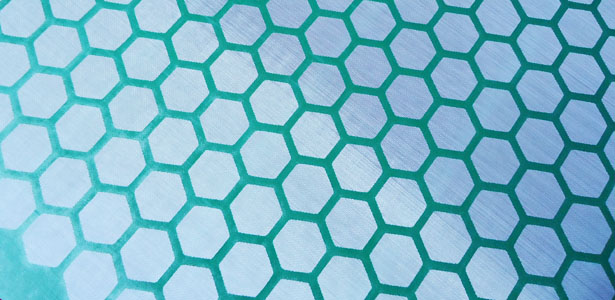

The size of our Mongoose shaker screen is 585*1165mm. The mesh our client ordered ranges from API 100 to API 230. Screen material is made of stainless steel 316, and frame material is top standard plastic injection. Screens will be packaged for 1 piece in one carton, and 30 pcs in one wooden case. They are manufactured according to both API and ISO standard. This kind of shaker screens also can be used in TR own shale shaker such as TRZS584 linear motion shaker and TRPS584 balanced elliptical motion shaker.

TR shaker screens are all passed strict inspection and with high quality package.

In addition to composite shaker screen, we also supply flat type and pyramid type shaker screen. TR shaker screens could be equivalent with many international brand like Derrick, Mi-Swaco, Nov Brandt, Kemtron, Brandt King Cobra. Our screens are widely used in trenchless HDD, Drilling Waste Management, city bored piling, oil & gas drilling, tunneling construction, Coal Bed Gas Solids Control System, micro-tunneling, environment protection, mining, Water Drilling etc. Contact with us for more information!